Adv. Funct. Mater: Thin film based on two-dimensional titanium carbide (MXene): the frontier of expanded functional thin film materials

1. Article overview

The two-dimensional titanium carbide (Ti3C2Tx) MXene film has a clear microstructure and chemical function, and provides the macroscopic application of nano Ti3C2Tx thin film. Ti3C2Tx film has attractive physical and chemical properties, which are conducive to device design, such as high conductivity, impressive volume capacitance, strong in-plane mechanical strength and high flexibility. This article reviews the attractive characteristics of ti3c2tx-based films produced by the layer-to-layer arrangement of nanosheets. Dedicated to key strategies to achieve the desired characteristics of functional films based on ti3c2tx, such as high and adjustable electrical conductivity, excellent mechanical properties, enhanced oxidation resistance and shelf life, hydrophilicity/hydrophobicity, adjustable porosity and Convenient processability. The basic aspects and research progress of thin film applications based on ti3c2tx are further discussed, and the relationship between its structural characteristics and the resulting performance is emphasized. Finally, the challenges and opportunities faced by ti3c2tx-based films in the future research, development and application are presented. A comprehensive understanding of these competitive characteristics and challenges will provide guidance and inspiration for the further development of functional films based on ti3c2tx and contribute to the advancement of MXene technology.

Two, graphic guide

The two-dimensional titanium carbide (Ti3C2Tx) MXene film has a clear microstructure and chemical function, and provides the macroscopic application of nano Ti3C2Tx thin film. Ti3C2Tx film has attractive physical and chemical properties, which are conducive to device design, such as high conductivity, impressive volume capacitance, strong in-plane mechanical strength and high flexibility. This article reviews the attractive characteristics of ti3c2tx-based films produced by the layer-to-layer arrangement of nanosheets. Dedicated to key strategies to achieve the desired characteristics of functional films based on ti3c2tx, such as high and adjustable electrical conductivity, excellent mechanical properties, enhanced oxidation resistance and shelf life, hydrophilicity/hydrophobicity, adjustable porosity and Convenient processability. The basic aspects and research progress of thin film applications based on ti3c2tx are further discussed, and the relationship between its structural characteristics and the resulting performance is emphasized. Finally, the challenges and opportunities faced by ti3c2tx-based films in the future research, development and application are presented. A comprehensive understanding of these competitive characteristics and challenges will provide guidance and inspiration for the further development of functional films based on ti3c2tx and contribute to the advancement of MXene technology.

Two, graphic guide

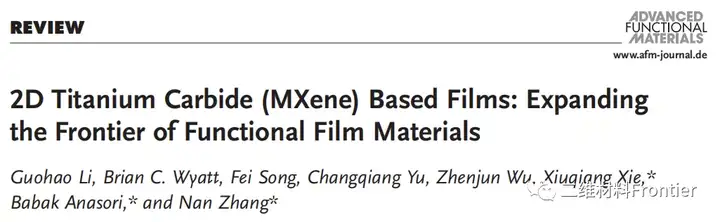

Figure 1. Summary of material development.

In the above figure, figure a) is a general schematic diagram of the formation of MXenes from the corresponding parent max phase. Figure b) Molecular structure model of monolayer ti3c2Tx. Figure c) Comparison of the conductivity of Ti3C2Tx, Mo2CTx, Ti2CTx, Nb4C3Tx, Nb2CTx, V2CTx, Mo2TiC2Tx and Mo2Ti2C3Tx. Figure d) Application of MXenes in different fields.

In the above figure, figure a) is a general schematic diagram of the formation of MXenes from the corresponding parent max phase. Figure b) Molecular structure model of monolayer ti3c2Tx. Figure c) Comparison of the conductivity of Ti3C2Tx, Mo2CTx, Ti2CTx, Nb4C3Tx, Nb2CTx, V2CTx, Mo2TiC2Tx and Mo2Ti2C3Tx. Figure d) Application of MXenes in different fields.

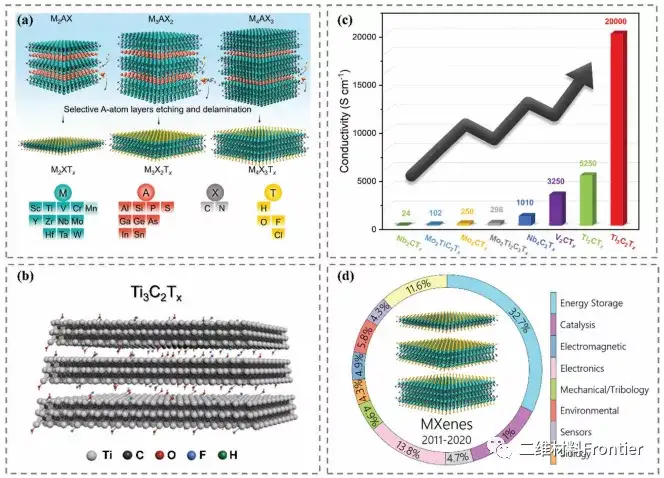

Figure 2. Performance test chart of various related materials.

In the above figure, figure a) the electrical transfer resistance (Rct) of ti3c2Tx, rGO and other combined electrodes. Figure b) Comparison of the conductivity of ti3c2Tx, graphene and reduced graphene oxide films. Figure c) The process of synthesizing large Ti3C2Tx flakes from large Ti3AlC2 particles. Figure d) After drying at 200°C for 6 hours, the electrical conductivity of the large Ti3C2Tx film coated on the blade with increasing thickness. Figure e) reported strength and conductivity of Ti3C2Tx-based thin film materials (usually Ti3C2Tx> strength and 90%).

In the above figure, figure a) the electrical transfer resistance (Rct) of ti3c2Tx, rGO and other combined electrodes. Figure b) Comparison of the conductivity of ti3c2Tx, graphene and reduced graphene oxide films. Figure c) The process of synthesizing large Ti3C2Tx flakes from large Ti3AlC2 particles. Figure d) After drying at 200°C for 6 hours, the electrical conductivity of the large Ti3C2Tx film coated on the blade with increasing thickness. Figure e) reported strength and conductivity of Ti3C2Tx-based thin film materials (usually Ti3C2Tx> strength and 90%).

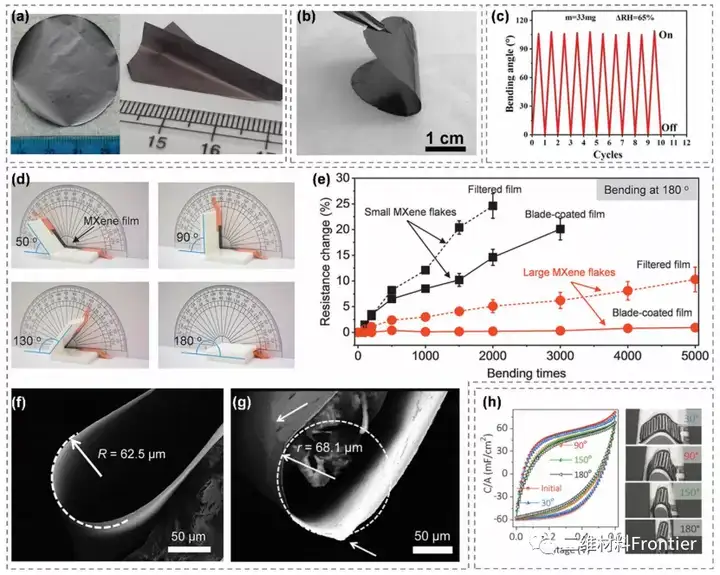

Figure 3. Mechanical flexibility test diagram of Ti3c2Tx film.

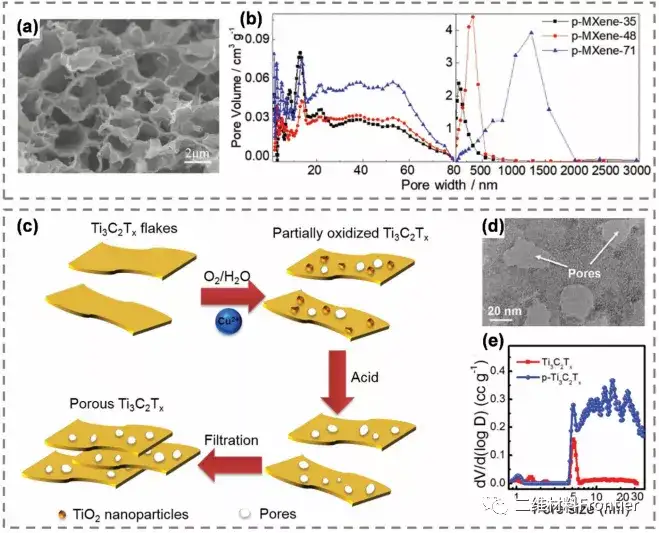

Figure 4. Structural characteristics of porous materials.

a) Scanning electron microscope image of porous ti3c2Tx. b) Pore size distribution derived from the results of nitrogen adsorption and mercury intrusion porosity measurement. c) Schematic diagram of a porous structure formed by chemical etching of ti3c2Tx sheet. d) Transmission electron microscope (TEM) image of chemically etched Ti3c2Tx flakes in 0.2m copper sulfate solution at room temperature. e) Pore size distribution of different samples.

a) Scanning electron microscope image of porous ti3c2Tx. b) Pore size distribution derived from the results of nitrogen adsorption and mercury intrusion porosity measurement. c) Schematic diagram of a porous structure formed by chemical etching of ti3c2Tx sheet. d) Transmission electron microscope (TEM) image of chemically etched Ti3c2Tx flakes in 0.2m copper sulfate solution at room temperature. e) Pore size distribution of different samples.

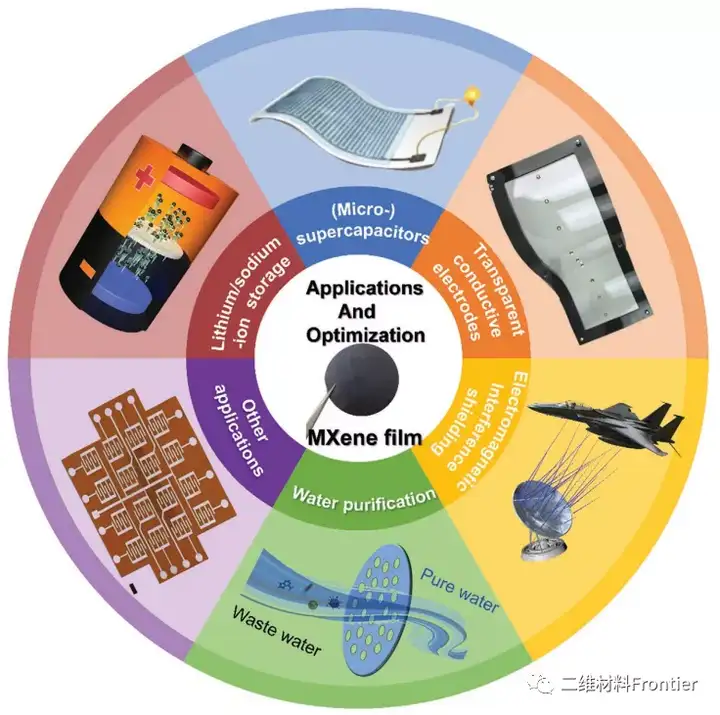

Figure 5. Application of titanium carbide (MXene)-based film.

3. Full text summary

In recent years, the unique properties of ti3c2tx-based films have developed rapidly in theoretical and experimental research. This article reviews the competitive characteristics, basic performance and engineering strategies of ti3c2tx-based films, which is expected to help its further development direction. In addition, the application progress of ti3c2tx-based materials for electrochemical lithium/sodium ion storage, (micro) supercapacitors, transparent conductive electrodes, water purification, EMI shielding and other applications is reviewed. These applications have been improved by controlling etching conditions, fine structure design, doping and surface modification. However, ti3c2tx-based films still have a clear gap between academic research and practical applications in terms of manufacturing capabilities and device performance. In order to narrow these key gaps, the author also analyzes the key challenges and prospects of manufacturing functional films based on ti3c2tx to promote the transformation from laboratory to industry.

Article link:

https://doi.org/10.1002/adfm.202105043

This information is sourced from the Internet for academic exchanges only. If there is any infringement, please contact us to delete it immediately.

3. Full text summary

In recent years, the unique properties of ti3c2tx-based films have developed rapidly in theoretical and experimental research. This article reviews the competitive characteristics, basic performance and engineering strategies of ti3c2tx-based films, which is expected to help its further development direction. In addition, the application progress of ti3c2tx-based materials for electrochemical lithium/sodium ion storage, (micro) supercapacitors, transparent conductive electrodes, water purification, EMI shielding and other applications is reviewed. These applications have been improved by controlling etching conditions, fine structure design, doping and surface modification. However, ti3c2tx-based films still have a clear gap between academic research and practical applications in terms of manufacturing capabilities and device performance. In order to narrow these key gaps, the author also analyzes the key challenges and prospects of manufacturing functional films based on ti3c2tx to promote the transformation from laboratory to industry.

Article link:

https://doi.org/10.1002/adfm.202105043

This information is sourced from the Internet for academic exchanges only. If there is any infringement, please contact us to delete it immediately.

+86-18915413828(WhatsApp&WeChat)

Previous: ACS Nano: Design of Bl