Application of Titanium Carbide MXene-based Transparent Conductive Electrode in Flexible Smart Window

1. Article overview

Among the various materials used in transparent and flexible devices, MXenes is attracting attention as a new class of candidate products. As a two-dimensional material, ti3c2TxMXene has special properties, making it a potential material with a wide range of applications in different fields. Due to its high conductivity, it can be used for transparent conductive electrodes (TCEs). In this study, MXenes etched with a highly concentrated acid at 50°C were spin-coated on a polyethylene terephthalate (PET) film and annealed at a moderate temperature of 170°C. Annealing significantly improves the adhesion of MXene to PET. These tce exhibited flake resistance of ~424Ω/sq. The transmittance of ~87%. The oxidation stability of the mxene coated PET film was studied, and it was found that the resistance change during this period was 30%. The flexibility test shows that at the 1000th cycle, the change in bending resistance is low (~1.5%), and after 1000 cycles, when the bending radius is ~3.9mm, the cumulative resistance change is ~20%. These transparent, flexible and conductive electrodes are used to manufacture flexible smart windows based on polymer dispersed liquid crystal (PDLC). The smart window made by curing the PDLC mixture sandwiched between the MXene electrodes is also flexible in the ON/OFF state. The mxene-based flexible smart window has good opacity in the OFF state and high transparency in the ON state. It displays a low threshold voltage of <10V at 60V, and a high transmittance of ~80%. The flexible smart window can work normally even at a bending radius of ~4mm.

Two, graphic guide

Among the various materials used in transparent and flexible devices, MXenes is attracting attention as a new class of candidate products. As a two-dimensional material, ti3c2TxMXene has special properties, making it a potential material with a wide range of applications in different fields. Due to its high conductivity, it can be used for transparent conductive electrodes (TCEs). In this study, MXenes etched with a highly concentrated acid at 50°C were spin-coated on a polyethylene terephthalate (PET) film and annealed at a moderate temperature of 170°C. Annealing significantly improves the adhesion of MXene to PET. These tce exhibited flake resistance of ~424Ω/sq. The transmittance of ~87%. The oxidation stability of the mxene coated PET film was studied, and it was found that the resistance change during this period was 30%. The flexibility test shows that at the 1000th cycle, the change in bending resistance is low (~1.5%), and after 1000 cycles, when the bending radius is ~3.9mm, the cumulative resistance change is ~20%. These transparent, flexible and conductive electrodes are used to manufacture flexible smart windows based on polymer dispersed liquid crystal (PDLC). The smart window made by curing the PDLC mixture sandwiched between the MXene electrodes is also flexible in the ON/OFF state. The mxene-based flexible smart window has good opacity in the OFF state and high transparency in the ON state. It displays a low threshold voltage of <10V at 60V, and a high transmittance of ~80%. The flexible smart window can work normally even at a bending radius of ~4mm.

Two, graphic guide

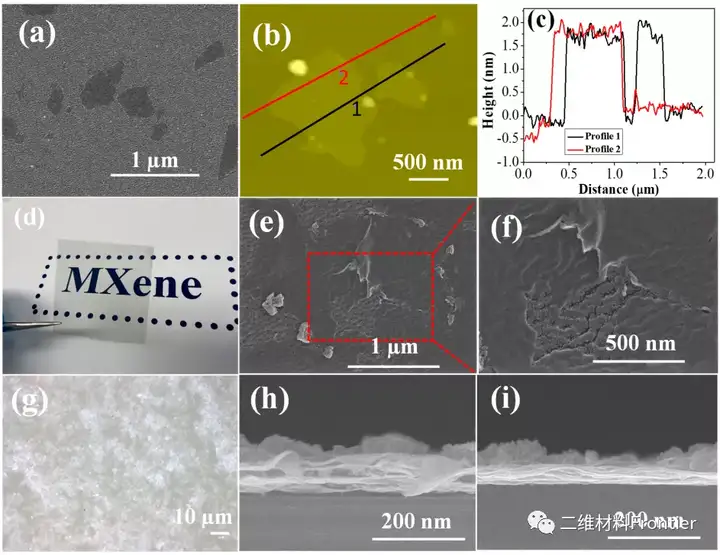

Figure 1. (a) FESEM image of separated MXene flakes. (b) AFM image of the peeled MXene flakes and (c) the corresponding line profile. (d) The photo image shows a transparent mxene-coated PET film. (e) The FESEM image and (f) the corresponding enlarged image show the patch status of MXene on the PET file. (g) The optical micrograph shows the random distribution of MXenes on PET. The cross-sectional FESEM image shows that the coated MXenes was annealed at 100°C (h) and (i) annealed at 170°C.

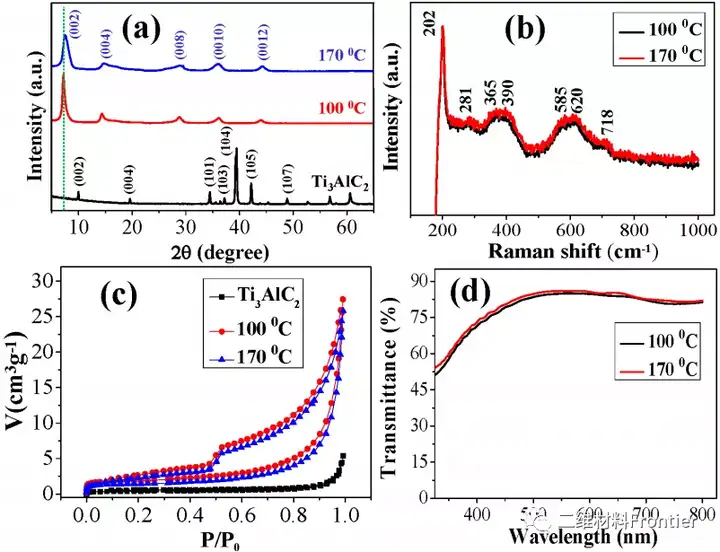

Figure 2. (a) XRD spectra of MAX phase and etched MXene. (b) Raman spectrum of etched MXene. (c) Adsorption and desorption (BET) curves of the etched MXene and MAX phases. (d) UV- and spectra of mxene-coated PET films processed at 100 and 170°C.

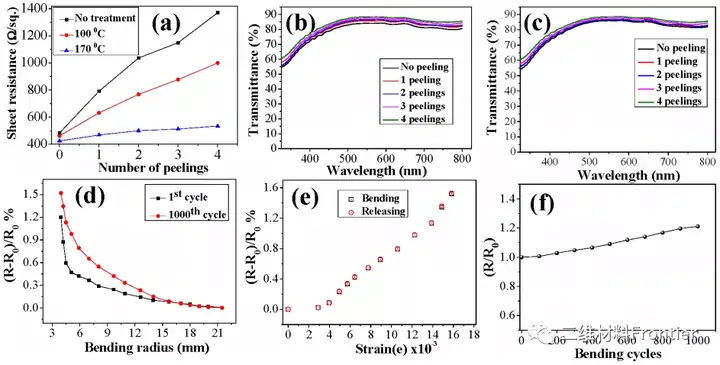

Figure 3. (a) Resistance change after repeated tape peeling with or without heat treatment. In the case of (b) untreated and (c) annealed at 170°C, UV- and transmittance spectra after each stripping. (d) The relative resistance changes in the first and 1000th bending cycles. (e) The change in relative resistance is plotted as a function of strain during bending and release. (f) To show fatigue behavior, we measured relative resistance (R/R0) as a function of bending cycles.

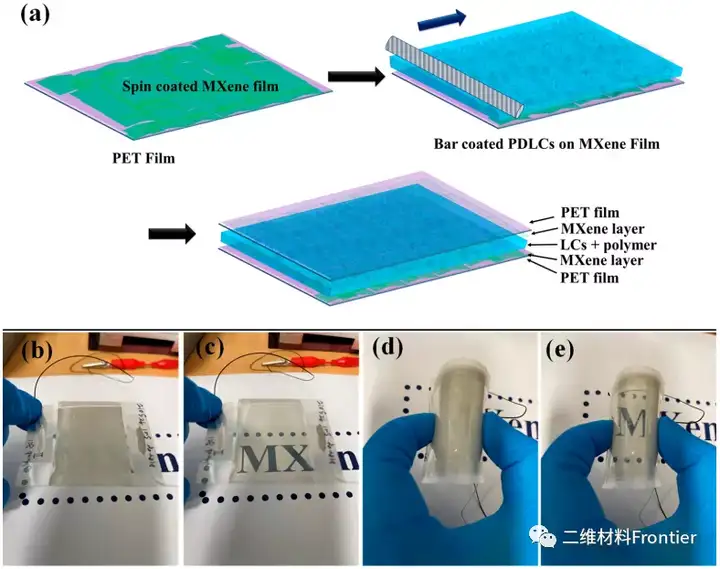

Figure 4. (a) Schematic diagram of mxene-based PDLCs prepared by rod-shaped coating method. (b) PDLC is opaque in OFF. (c) At 60V, it becomes transparent in the ON state. When it was bent, proper switching behavior was confirmed in (d) OFF and (e) ON states.

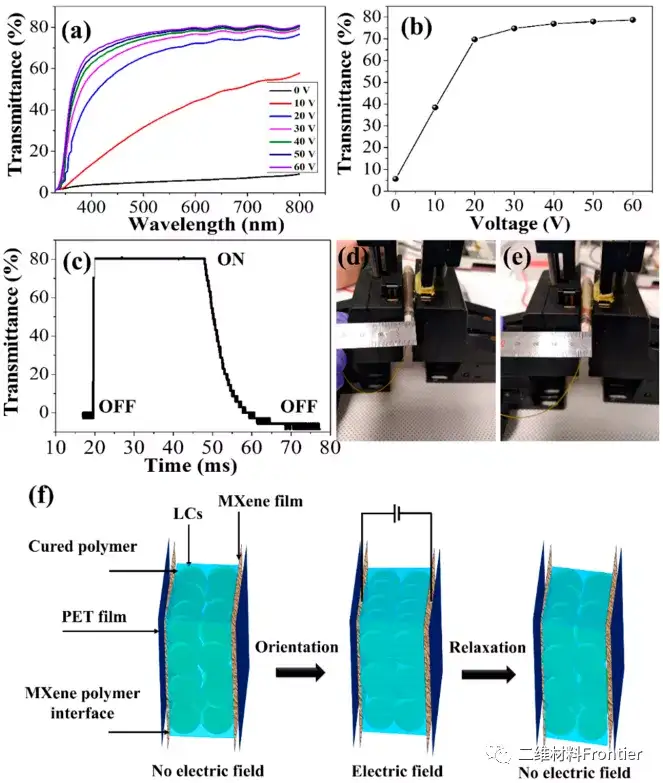

Figure 5. (a) The UV-visible transmission spectra of mxene-based pdlc under different voltages were measured. (b) Draw the curve of voltage and light transmittance at 550nm. (c) The switch response behavior is recorded as a function of time. With the help of the XYZ translator, the bending test is performed in (d)OFF and (e)ON states. (f) Switch mechanism of PDLCs based on mxene.

3. Full text summary

In this study, a transparent, flexible and conductive electrode based on ti3c2Txmxene was prepared on a PET substrate. By adding LCs and NOA65 monomer, its application in flexible smart windows was proposed. MXene coated PET film, prepared by etching with highly concentrated acid with MXene, has high oxidation stability under 28 days of environmental conditions. Compared with untreated films, spin-coated MXene films annealed at 170°C are flexible, strong and stable. The light transmittance of the MXene film is ~87%, and the sheet resistance is ~424Ω/sq. Reliable. When the bending strain with a bending radius of 3.9 mm is 0.017, the bending of the MXene film shows a <1.5% change in resistance. After 1000 bending cycles, the resistance change increased to ~20%, indicating good fatigue resistance. The relative resistance change in the 1000th cycle was ~1.5%, which was only 0.3% higher than the relative resistance change of the first bending cycle (~1.2%) %. The mixture of LC and monomer sandwiched between mxene is cured under ultraviolet light to prepare PDLCs. These smart windows have a threshold voltage of <10V and a saturation voltage of ~50V, and are flexible even when the bending radius is ~4mm. Therefore, although the photoelectric properties of mxene-based PDLCs are equivalent to those of ito-based PDLCs, their mechanical properties are better than this. This research opens up new horizons for mxene-based TCEs as cost-effective and easy-to-manufacture alternatives in various applications.

In this study, a transparent, flexible and conductive electrode based on ti3c2Txmxene was prepared on a PET substrate. By adding LCs and NOA65 monomer, its application in flexible smart windows was proposed. MXene coated PET film, prepared by etching with highly concentrated acid with MXene, has high oxidation stability under 28 days of environmental conditions. Compared with untreated films, spin-coated MXene films annealed at 170°C are flexible, strong and stable. The light transmittance of the MXene film is ~87%, and the sheet resistance is ~424Ω/sq. Reliable. When the bending strain with a bending radius of 3.9 mm is 0.017, the bending of the MXene film shows a <1.5% change in resistance. After 1000 bending cycles, the resistance change increased to ~20%, indicating good fatigue resistance. The relative resistance change in the 1000th cycle was ~1.5%, which was only 0.3% higher than the relative resistance change of the first bending cycle (~1.2%) %. The mixture of LC and monomer sandwiched between mxene is cured under ultraviolet light to prepare PDLCs. These smart windows have a threshold voltage of <10V and a saturation voltage of ~50V, and are flexible even when the bending radius is ~4mm. Therefore, although the photoelectric properties of mxene-based PDLCs are equivalent to those of ito-based PDLCs, their mechanical properties are better than this. This research opens up new horizons for mxene-based TCEs as cost-effective and easy-to-manufacture alternatives in various applications.

Article link:

https://doi.org/10.1021/acsami.1c12100

This information is sourced from the Internet for academic exchanges only. If there is any infringement, please contact us to delete it immediately.

https://doi.org/10.1021/acsami.1c12100

This information is sourced from the Internet for academic exchanges only. If there is any infringement, please contact us to delete it immediately.

+86-18915413828(WhatsApp&WeChat)

Previous: Peng Fei/Tu Yingfeng A