The latest Review of AM: programmable Mechanical active Hydrogel-based Materials

[background].

Programmable mechanically active materials (MAM) can sense external stimuli and convert them into mechanical output, or in turn can detect mechanical stimuli and respond to optical or other changes in the materials appearance.Programmable MAM is a subset of response materials, which provides potential for the next generation of robots and intelligent systems. The team of Professor Khalid Salaita of Emory University in the United States discussed the composition of hydrogel MAM and the top-down and bottom-up approaches for programming these materials.

Then the basic principles of engineering responsiveness in MAMS are discussed, including light, heat, magnetic, electrical, chemical and mechanical stimulation. Some advantages and disadvantages of different responsiveness are compared. Finally, the emerging applications of hydrogel-based MAM in the recently published literature and the future prospects of MAM research are summarized. The article Programmable Mechanically Active Hydrogel-Based Materials is published in the journal Advanced Materials. In this review, the team first describes the chemical composition and fabrication of hydrogel-based MAM, and then specific methods for achieving programmability. Then, the detailed classification of response mechanism is provided, and the close relationship between material structure and its response behavior is discussed. Finally, the author summarizes the current application of MAM in many disciplines, as well as the future direction and application of mechanical response hydrogel.

[guide to the main picture].

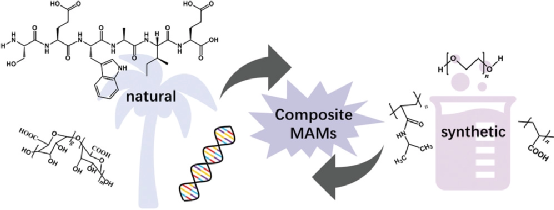

Figure 1.

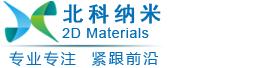

Common components of mechanically active materials (MAM). Many types of hydrogel polymers can form programmable MAM, including naturally derived polymers such as alginate polysaccharides, peptides and DNA (left), synthetic polymers such as N-isopropylacrylamide (NIPAM) or polyethylene glycol (PEG) (right), or combinations of different polymer types (middle).

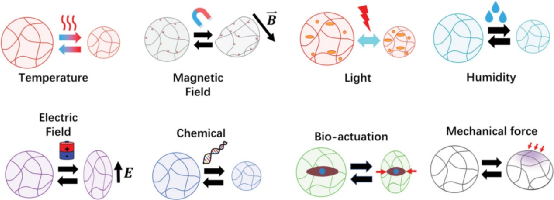

Figure 2.

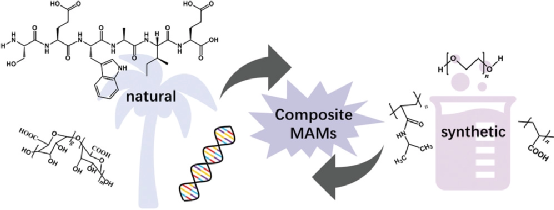

MAM response diagram based on hydrogel. Mechanical drives in MAM can be triggered by various stimuli, depending on the material design. Different MAM respond to heating, magnetic or electric field, light, hydration, oxidation, specific molecules in the solution, pH values, ionic strength and even external mechanical forces.

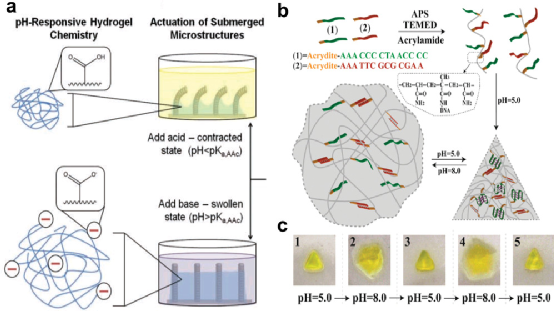

Figure 3.

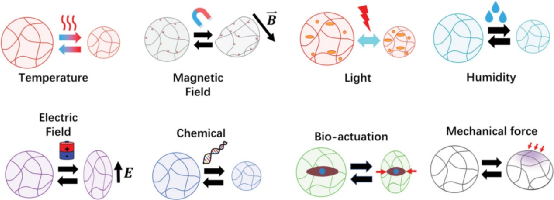

PH responds to MAM. A) the chip of polymer microstructure. The changes of pH were detected by microcolumn hydrogel on the chip. B) MAM based on DNA hydrogel has the function of shape memory in response to different pH conditions. The decrease of pH value will lead to the recombination of DNA base pairs and lead to gel deformation. C) this reaction is highly reversible and repeatable.

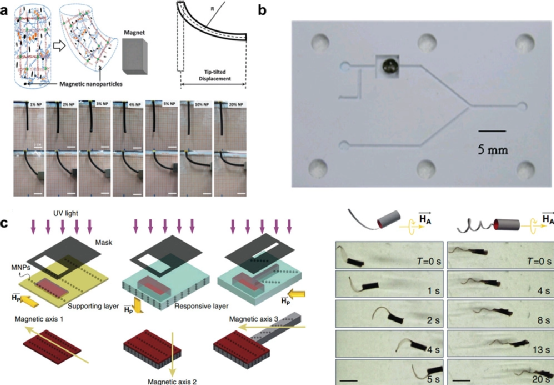

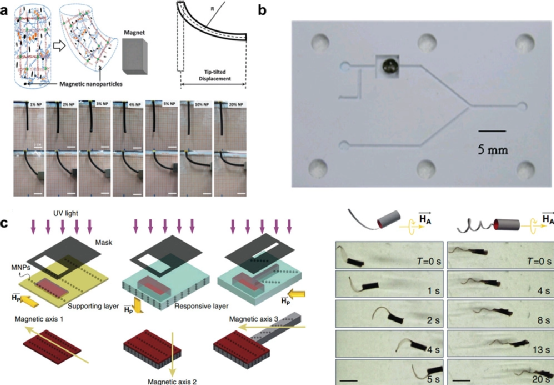

Figure 4.

Magnetic field response MAM. A) Polyacrylamide hydrogel MAM embedded with randomly distributed MNP. The material is so responsive that it bends in the direction of the applied magnetic field even at low MNP content. B) Fe3O4/pNIPAM composites (black spots) that can open / close microfluidic channels when an alternating magnetic field is applied. The field heats the iron oxide particles, resulting in the detumescence of the pNIPAM polymer that opens the channel. C) (left) Magnetic response MAM can also be manufactured with pre-organized MNP. This causes sensitivity to the direction of the applied magnetic field (right), resulting in a highly sensitive and controllable soft robot.

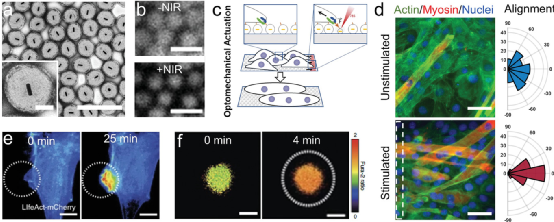

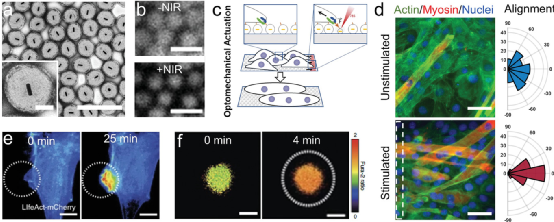

Figure 5.

Photoresponsive MAM instructs cell behavior. A) the photomechanical actuator (OMA) is Au-pNIPMAM composite nanoparticles, which will contract when exposed to NIR light. B) when exposed to NIR light, the fluorescence labeling of OMA provides evidence of particle collapse. C) MAM promotes cell attachment and applies forces with high spatial precision to study the role of mechanics in cell activity of various cell types. D) repeated stimulation of myoblasts within 5 days enhanced maturation markers (left), such as myosin expression (red) and multinucleation (nucleus, blue), as well as cell arrangement (actin, green; histogram, right). E) fibroblasts respond to short-term mechanical stimuli by extending in the direction of stimulation and increasing actin polymerization. F) Mechanical stimulation of T cells can significantly enhance calcium signal, which is an important marker of T cell activation.

[summary].

What is the future of MAM? It is not easy to predict the development of this field in the next few years, because the new development of MAM is very fast. An important area in this area is honing the manufacturing techniques used to create MAM. At present, the vast majority of MAM are in the form of thin films, rods and other simple shapes. While complex architectures have been achieved by assembling these basic shapes or creating well-designed self-assembly structures, improved 3D printers and lithography technologies over the next few years are likely to allow the creation of exciting new MAM geometry.

This information is from the Internet for academic exchange only. if there is any infringement, please contact us to delete it immediately.

Programmable mechanically active materials (MAM) can sense external stimuli and convert them into mechanical output, or in turn can detect mechanical stimuli and respond to optical or other changes in the materials appearance.Programmable MAM is a subset of response materials, which provides potential for the next generation of robots and intelligent systems. The team of Professor Khalid Salaita of Emory University in the United States discussed the composition of hydrogel MAM and the top-down and bottom-up approaches for programming these materials.

Then the basic principles of engineering responsiveness in MAMS are discussed, including light, heat, magnetic, electrical, chemical and mechanical stimulation. Some advantages and disadvantages of different responsiveness are compared. Finally, the emerging applications of hydrogel-based MAM in the recently published literature and the future prospects of MAM research are summarized. The article Programmable Mechanically Active Hydrogel-Based Materials is published in the journal Advanced Materials. In this review, the team first describes the chemical composition and fabrication of hydrogel-based MAM, and then specific methods for achieving programmability. Then, the detailed classification of response mechanism is provided, and the close relationship between material structure and its response behavior is discussed. Finally, the author summarizes the current application of MAM in many disciplines, as well as the future direction and application of mechanical response hydrogel.

[guide to the main picture].

Figure 1.

Common components of mechanically active materials (MAM). Many types of hydrogel polymers can form programmable MAM, including naturally derived polymers such as alginate polysaccharides, peptides and DNA (left), synthetic polymers such as N-isopropylacrylamide (NIPAM) or polyethylene glycol (PEG) (right), or combinations of different polymer types (middle).

Figure 2.

MAM response diagram based on hydrogel. Mechanical drives in MAM can be triggered by various stimuli, depending on the material design. Different MAM respond to heating, magnetic or electric field, light, hydration, oxidation, specific molecules in the solution, pH values, ionic strength and even external mechanical forces.

Figure 3.

PH responds to MAM. A) the chip of polymer microstructure. The changes of pH were detected by microcolumn hydrogel on the chip. B) MAM based on DNA hydrogel has the function of shape memory in response to different pH conditions. The decrease of pH value will lead to the recombination of DNA base pairs and lead to gel deformation. C) this reaction is highly reversible and repeatable.

Figure 4.

Magnetic field response MAM. A) Polyacrylamide hydrogel MAM embedded with randomly distributed MNP. The material is so responsive that it bends in the direction of the applied magnetic field even at low MNP content. B) Fe3O4/pNIPAM composites (black spots) that can open / close microfluidic channels when an alternating magnetic field is applied. The field heats the iron oxide particles, resulting in the detumescence of the pNIPAM polymer that opens the channel. C) (left) Magnetic response MAM can also be manufactured with pre-organized MNP. This causes sensitivity to the direction of the applied magnetic field (right), resulting in a highly sensitive and controllable soft robot.

Figure 5.

Photoresponsive MAM instructs cell behavior. A) the photomechanical actuator (OMA) is Au-pNIPMAM composite nanoparticles, which will contract when exposed to NIR light. B) when exposed to NIR light, the fluorescence labeling of OMA provides evidence of particle collapse. C) MAM promotes cell attachment and applies forces with high spatial precision to study the role of mechanics in cell activity of various cell types. D) repeated stimulation of myoblasts within 5 days enhanced maturation markers (left), such as myosin expression (red) and multinucleation (nucleus, blue), as well as cell arrangement (actin, green; histogram, right). E) fibroblasts respond to short-term mechanical stimuli by extending in the direction of stimulation and increasing actin polymerization. F) Mechanical stimulation of T cells can significantly enhance calcium signal, which is an important marker of T cell activation.

[summary].

What is the future of MAM? It is not easy to predict the development of this field in the next few years, because the new development of MAM is very fast. An important area in this area is honing the manufacturing techniques used to create MAM. At present, the vast majority of MAM are in the form of thin films, rods and other simple shapes. While complex architectures have been achieved by assembling these basic shapes or creating well-designed self-assembly structures, improved 3D printers and lithography technologies over the next few years are likely to allow the creation of exciting new MAM geometry.

This information is from the Internet for academic exchange only. if there is any infringement, please contact us to delete it immediately.

+86-18915413828(WhatsApp&WeChat)

Previous: Weng Gengsheng of Ning